.

Home

All Products

HIWIN EGR20T 20mm Linear Guide Rail Fastening from below for CNC Machine. Choose your required length.

FOR OTHER SIZES, CONTACT US.

Condition : Used - Tested

Comes with 90 days Warranty from Voltatek.

Price in CAD.

Found a lower price? Write to : info@voltatek.ca

Condition : Used - Tested

Comes with 90 days Warranty from Voltatek.

Price in CAD.

Found a lower price? Write to : info@voltatek.ca

Condition : Used - Tested

Comes with 90 days Warranty from Voltatek.

Price in CAD.

Found a lower price? Write to : info@voltatek.ca

SFU2005 Ball Screw 20mm Diameter, 5mm lead. Choose your length. With Flange Nut BK15/BF15 End Machined.

FOR OTHER SIZES, CONTACT US.

CNC Sliding Table Z axis stage travel L 100-2000mm HGR20 linear guides SFU1605 SFU1610 ball screw Linear Actuator Bundle Kit

WORLDWIDE SHIPPING AVAILABLE

HIWIN HGW35CC Sliding Block for 35mm Linear Guide Rail (HGR35) for CNC

WORLDWIDE SHIPPING AVAILABLE

HIWIN HGW30CC Sliding Block for 30mm Linear Guide Rail (HGR30) for CNC

WORLDWIDE SHIPPING AVAILABLE

HIWIN HGH35CA Sliding Block for 35mm Linear Guide Rail (HGR35) for CNC

WORLDWIDE SHIPPING AVAILABLE

HIWIN HGH30CA Sliding Block for 30mm Linear Guide Rail (HGR30) for CNC

WORLDWIDE SHIPPING AVAILABLE

Condition : Used - Tested

Comes with 90 days Warranty from Voltatek.

Price in CAD.

Found a lower price? Write to : info@voltatek.ca

HIWIN HGW25CC Sliding Block for 25mm Linear Guide Rail (HGR25) for CNC

HIWIN HGH25CA Sliding Block for 25mm Linear Guide Rail (HGR25) for CNC

WORLDWIDE SHIPPING AVAILABLE

MBA10 MBA12 MBL10 MBL12 Nema 23 Motor Mounting Bracket for Ball Screw support.

CHOOSE YOUR TYPE:

ER11 Tool Chuck for CNC Router Spindle Motor.

CHOOSE MOTOR SHAFT DIAMETER

500W Air Cooled Spindle Motor 0.5kW for CNC Router Engraver

Spindle Mounting Bracket for CNC Router 52mm

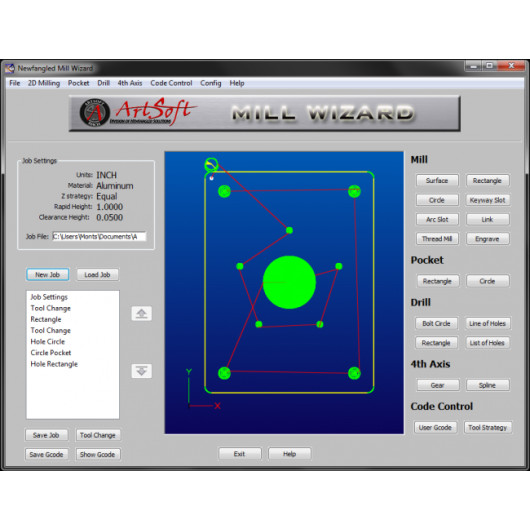

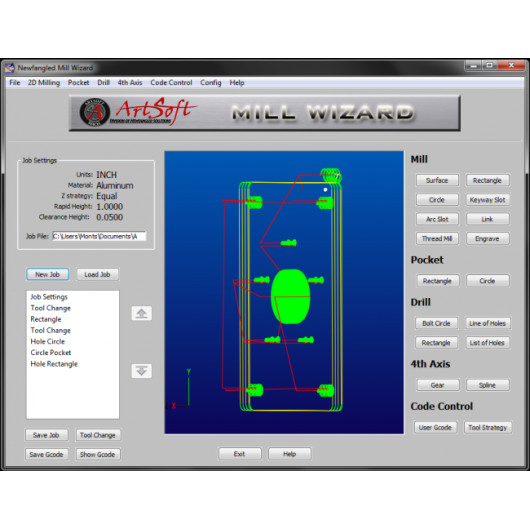

CNC 4 Axis USB Controller Board for Router Engraver, MACH3 Ready

HIWIN EGR20 20mm Linear Guide Rail for CNC Machine. EGR20R Mounting from Top. Choose your required length.

FOR OTHER SIZES, CONTACT US.